Valve sealing surface grinding is a key step to ensure sealing performance

The sealing performance of the valve directly affects the control effect of the fluid medium and the safe operation of the system, the grinding of the valve sealing surface is one of the important means to ensure its sealing performance, its main purpose is to eliminate the uneven sealing surface, defects and particles, improve the surface smoothness and roughness, so as to achieve better sealing performance. The grinding valve sealing surface can usually achieve dimensional accuracy of 0.001~0.003mm, geometric accuracy (such as roughness) of 0.001mm, and surface roughness of 0.1~0.008.

The basic principles of grinding

1. Grinding process

During the grinding process, the lashing tool and the sealing ring surface are well fitted together, and the lashing tool makes complex grinding movement along the fitted surface. An abrasive is placed between the lashing tool and the sealing ring surface. When the lashing tool and the sealing ring surface move relative to each other, some of the abrasive particles in the lashing tool and the sealing ring surface slide or roll, cutting off a thin layer of metal on the sealing ring surface. Grinding is not only the mechanical processing of metal by abrasives, but also the chemical action. The oil in the grinding agent can form an oxide film on the machined surface, thus speeding up the grinding process.

2. Grinding motion

When the lashing tool moves relative to the surface of the sealing ring, the relative sliding distance of each point on the surface of the sealing ring to the lashing tool should be the same, and the direction of the relative movement should be constantly changed. This mode of movement avoids the abrasive particle repeating its own movement track on the surface of the sealing ring, reduces the obvious wear marks, and thus reduces the roughness of the sealing ring surface.

3. Grinding speed

The speed of grinding directly affects the grinding efficiency. The grinding speed is usually 10~240m/min, but for high-precision workpieces, the grinding speed is generally not more than 30m/min. The grinding speed of the valve sealing surface is related to the material of the sealing surface, and different materials have different recommended grinding speeds.

4. Grinding pressure

The grinding efficiency increases with the increase of grinding pressure, but the grinding pressure can not be too large, generally 0.01 ~ 0.4MPa. The larger value is taken for rough grinding and the smaller value is taken for fine grinding.

5. Grinding allowance

Because grinding is a finishing process, the cutting amount is very small. The size of the grinding allowance depends on the machining accuracy and surface roughness of the previous process. Under the premise of ensuring the removal of the processing marks of the previous process and correcting the geometric error of the sealing ring, the smaller the grinding margin, the better.

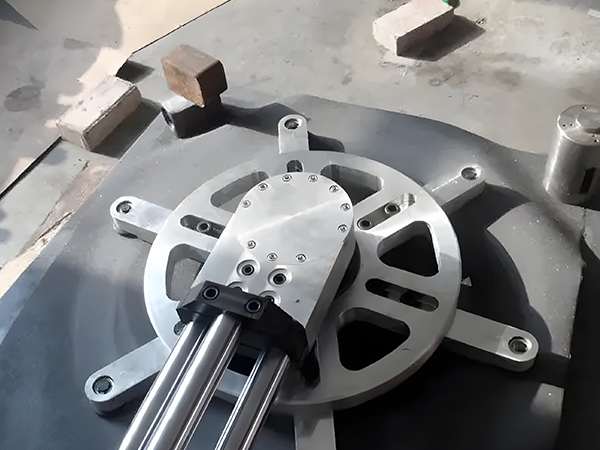

Grinding method steps

1, preparation: confirm the type and structure of the valve, check the damage of the valve sealing surface and the surface roughness. At the same time, prepare the grinding tools, grinding materials and corresponding lubricants.

2, clean the surface: use the appropriate cleaning agent to clean the sealing surface to remove the dirt and grease on the surface to ensure the accuracy of the grinding effect.

3, grinding tool selection: according to the shape and material of the valve sealing surface, choose the appropriate grinding tools, such as grinding wheels, grinding pieces, etc.

4, grinding operation: the grinding tool is fixed on the appropriate grinding equipment, according to the shape of the valve sealing surface and damage, the appropriate grinding operation. It can be operated manually or with mechanical assistance.

5, grinding degree control: according to the actual situation, control the degree of grinding, generally should ensure the smooth sealing surface of the valve.